Common faults and analysis of screen printing (One)

Dec. 11, 2019

As the earliest printing process, silk screen printing has a long history. In the process of using technology, there are often failures, and silk screen failures have a single cause, but more are the result of the intricate and complex causes.

First, paste

Paste printing is also called blocking, which refers to the phenomenon that the screen printing plate can not transfer the ink to the substrate during printing. The occurrence of this phenomenon will affect the print quality, and even in severe cases, normal printing may not be performed. The causes of scumming during screen printing are intricate. The causes of scumming are analyzed from the following aspects.

1. Reasons for printed matter

Screen printing substrates are various, and the texture characteristics of substrates are also a factor before the phenomenon of offset. For example: Paper, piles, glass printing mesh, fabrics and other substrates have low surface smoothness and poor surface strength. It is easier to produce powder and lint during the printing process, so it is made into paste.

2.Causes of workshop temperature and humidity ink properties

Screen printing workshops require a certain temperature and relative humidity. If the temperature is high and the relative humidity is low, the volatile solvent in the ink will evaporate quickly, and the viscosity of the ink will become high, thereby blocking the mesh. Another point that should be noted is that if the downtime is too long, the phenomenon of scumming will also occur. The longer the time, the more serious the scumming. Secondly, if the ambient temperature is low, the ink fluidity is poor and it is easy to cause offset.

3. Reasons for screen printing plates

The finished flat bed polyester screen printing mesh can be used after being rinsed with water and dried before use. If the plate is left unprinted for a long time after making it, the dust will stick to it more or less during the preservation process. If it is not cleaned during printing, it will cause paste.

4. Reasons for printing pressure

Excessive embossing force during the printing process will bend the squeegee. The squeegee is not in line contact with the screen printing plate and the substrate, but in surface contact. In this way, the ink cannot be scraped clean with each scraping, leaving a residue. Ink, after a certain period of time, it will condense and cause paste.

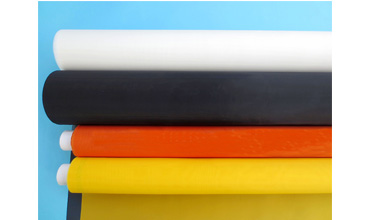

Polyester Screen Printing Mesh

5. Reasons for improper clearance between screen printing plates and substrates

The gap between the screen printing plate and the substrate should not be too small. The screen gap cannot be separated from the substrate after scratching. When the screen printing plate is lifted, a certain amount of ink adheres to the bottom of the printing plate.

6.Ink reason

When the particles of the pigment and other solid materials in the screen printing ink are large, the phenomenon of blocking the mesh is easy to occur. In addition, the number of screen meshes and through-hole areas selected is smaller than the particle size of the ink, and it is also one of the reasons that the coarser particles of ink are not easy to pass through the polyester screen printing mesh and the network is blocked.

The ink dries too fast during the printing process, which can easily cause scumming failure. Especially when using volatile drying inks, this phenomenon is more prominent, so the appropriate solvent must be selected to control the drying speed when printing.

In the printing process, the increase of the viscosity of the ink causes the paste, the main reason is that the ink solvent on the plate evaporates, which causes the ink viscosity to increase, and the phenomenon of screen sealing occurs. If the area of the text is small and the ink consumption on the screen printing plate is small, it is easy to cause paste. The countermeasure is to often use new ink.