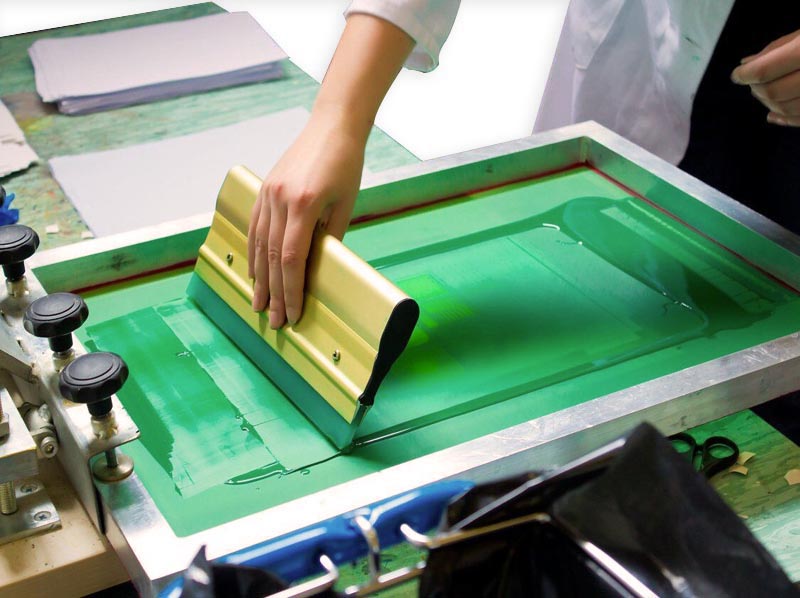

In Screen Printing, How to Avoid Printing Size Expansion?

Jul. 02, 2020

After screen printing, sometimes the size of printed matter will expand. The main reason for the enlargement of the printing size is that the ink viscosity is relatively low and the fluidity is too large; the enlargement of the size of the screen printing plate at the time of production is also one of the reasons for the enlargement of the printing size. In order to avoid excessive fluidity of the ink, resulting in large print size, a certain amount of thickener can be added to the ink to reduce the fluidity of the ink; fast-drying ink can also be used to speed up the drying speed of the ink after printing. When making a screen printing plate, we must ensure the quality of the screen printing plate.

Why does the stripping effect differ when using the same screen printing mesh, photosensitive glue, and stripping solution? When this happens, one is affected by various conditions in the plate making processes, such as drying temperature, drying time and printing time; second is affected by the performance of the ink, some screen printing inks will have a chronic dark reaction with the film, so that The hydrophilic group -OH in the adhesive layer gradually decreases, which makes it difficult to remove the film; the third is that the screen is stored for too long, and the adhesive film ages and dehydrates. Why does the exposed film fall off when it is rinsed? The exposed adhesive film has a shedding failure during washing, which is mainly caused by the following reasons: underexposure, sensitization of the photosensitive adhesive, and failure of the photosensitizer.

Therefore, to ensure that the exposure effect reaches the entire screen coating, the dyeing net and copper net must increase the exposure time, and ensure that a sufficient amount of photosensitizer and latex are thoroughly mixed. What are the processes of post-production processing? There are the following:

1. Check the quality of the screen printing plate, including whether the graphics and text are all developed, whether there are burrs, defects, broken pens, and whether the mesh is blocked, etc., if the above situation is found, it should be remedied in time. If it cannot be remedied, consider remaking the plate to ensure printing quality.

2. Check whether there are bubbles or trachoma in the omentum and whether the four sides near the frame are sealed. The air bubbles and trachoma should be remedied in time, and the unscreened silk screen on all four sides should be sealed to avoid ink leakage during printing.

3. Check whether the printing positioning marks meet the requirements of the printed order. Use adhesive tape to stick the bonding part of the screen and the frame to improve the adhesion of the screen and the frame. Paste the platemark, paste the platemark on the position of the unified frame, the platemark should generally indicate the following content: the name of the print, the color, the number of colors, the number of screens, the number of lines of the plate, the type of photosensitive material, the date of making the plate, platemaker, etc.

The above information is provided by a silk screen printing mesh supplier.