Do You Know Screen Printing?

Jan. 08, 2020

Polyester screen printing mesh wholesaler to share with you: Screen printing is also known as orifice plate printing. The formation of holes depends on the opening of the screen.

The performance of the screen affects the quality of screen printing, such as the screen material, mesh number, opening degree, and aperture ratio, etc., have a great impact on the ink transfer of screen printing.

Screen printing is commonly used: silk screen, nylon (polyurethane polyurethane) screen, polyester screen stainless steel screen and so on.

Silk screen is also called silk screen. Silk screen is woven from natural silk. The earliest screen printing material.

Advantages: strong water resistance, a certain moisture absorption, simple stretch net operation, and good binding with the photosensitive adhesive,

Disadvantages: Poor abrasion resistance and chemical resistance, easy to age and brittle, stretched screen is low tension, low printing resistance, high cost.

It is used less now and has been replaced by synthetic fibers.

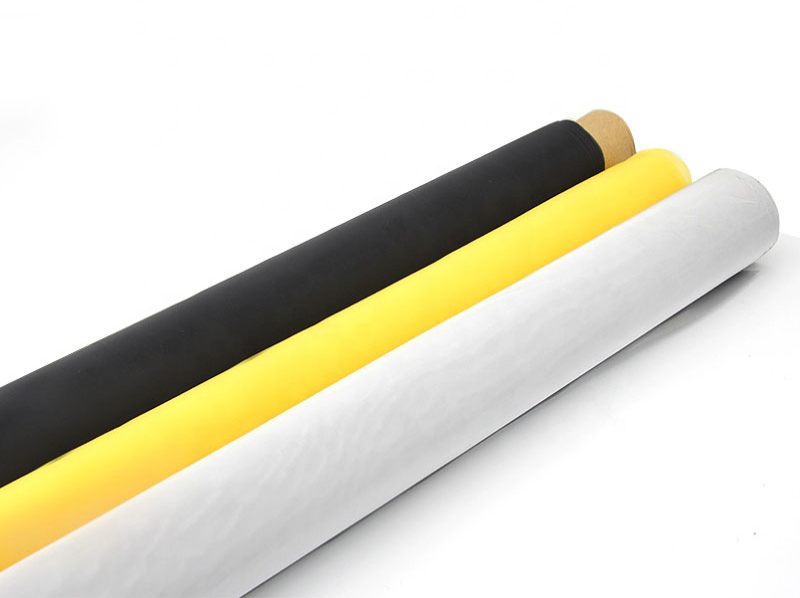

Polyester Screen Printing Mesh

Nylon wire mesh, also known as nylon wire mesh, is a monofilament fabric that is heat-resistant and dimensionally stable after weaving. Plain weave up to 380 mesh, Twill weave up to 330 mesh

Features: Smooth surface and good ink permeability. Fine printing patterns can be obtained with large viscosity and large particles. Used and fine mesh woven fine mesh screen is suitable for fine pattern printing. Tensile strength, nodular fastness, elastic abrasion resistance and long life. Acid and chemical resistance, good resistance to organic solvents, easy to reuse, especially strong resistance to alkali.

Pay attention to the problems: Compared with silk and polyester screen mesh, the specific elongation is larger. When stretching the net, pay attention to increase the tension of the net, and at the same time, the contraction force will increase. Therefore, a strong screen frame and a screen drawing machine should be used. Low heat resistance. It is not resistant to strong acids, formic acid, and ultraviolet rays, which have a slight effect on it. Please keep it away from light.

Also known as polyester screen, its characteristics: small pulling depth, strong elasticity, single-wire screen is suitable for printing integrated circuits, back-mold semiconductors, and can be supervised and printed. Tensile strength, structural strength, resilience, and printing resistance are all good. It has sufficient chemical resistance, especially acid and organic solvent resistance, and it is as renewable as nylon mesh.

Low hygroscopicity, hardly affected by moisture, heat resistance is higher than nylon, and less affected by ultraviolet rays.

The "mesh" is the unit of specification of the wire mesh, and refers to how many holes there are in a length of 1 inch (25.4 mm). Millimeter is a simple unit of length.

Since there are corresponding technical standards for the production of wire mesh, and different sizes of wire meshes have prescribed wire diameters, so the wire meshes of different meshes are simply stated. Each hole does not count the actual wire diameter of the wire.

Net yarn is divided into these two weaving methods. PW stands for plain weaving and TW stands for diagonal weaving. There are two types of white and yellow: W = white Y = yellow.

Polyester net yarn has the characteristics of uniform mesh, low elasticity and strong solvent resistance, which is suitable for screen printing with high degree of fine printing. The company's products are sold at factory prices with quality assurance. Welcome new and old customers to order! Replacement if there is a quality problem! Please rest assured!

Polyester net is a special net for printing. The tension of the net is balanced. The polyester screen printing mesh has a clear printing effect.